Applications

Bringing It All Together

Combining Preventive, Predictive, and Precision Maintenance in a comprehensive maintenance strategy yields tangible results for your organization. The trick is understanding how they should be combined so they can achieve these results.

Many facilities have focused on one or two of the three “Ps” of maintenance improvement. The three “Ps” include Preventive, Predictive, and Precision Maintenance. The problem is that in order to produce a step change in performance, the site needs to address all three and allow them to work together to drive improvement. We will look at each to discover its benefits and limitations and then bring them together to show the synergies of “and”.

Preventive Maintenance

First, let us look at Preventive Maintenance, or PM as it is commonly known. This is the first and most basic of the “Ps”. The PM mindset was the beginning of proactive maintenance, prior to Preventive Maintenance our world was run to failure only. For example, if a wagon cart was designed and built, it would be used until the axle broke. Then the axle would be replaced and the cycle restarted. People noticed that as time passed, items failed. Their belief was that if they could measure the time and replace the component prior to this failure, then the equipment could be more reliable. From our cart example, a farmer might notice that axles fail after four years of use; therefore, he would replace the axle after three years to lower the likelihood of a failure in the field.

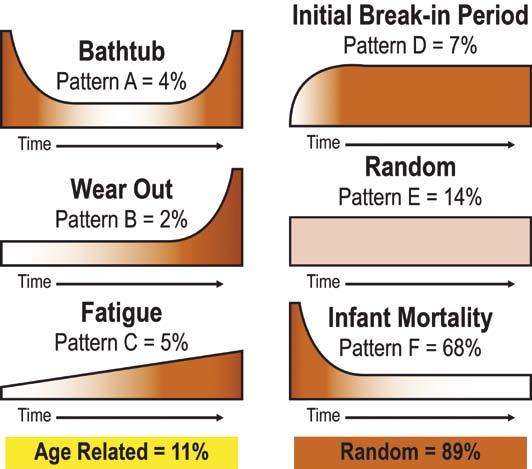

The tasks associated with PM include time-based replacement and time-based intrusive and non-intrusive visual inspections. Intrusive inspections are the inspections where the asset is shut down and disassembled for inspection. PM works very effectively with the wear out and fatigue failure curves shown in Figure 1. However, only 7 % of the failure modes in the original Nowlan and Heap study fall into those categories.

If that data surprises you and you would like to learn more, the Nowlan and Heap study, which was the foundation of Reliability Centered Maintenance (RCM), can be found on various Internet sites, including my blog at www.reliabilitynow.com in the links section.

Predictive Maintenance

The second of the “Ps” is Predictive Maintenance. Predictive Maintenance (PdM) is all about identifying the existence of a failure in a non-intrusive manner, preferably while the equipment is running. One of the benefits of PdM is that in many cases it does not require downtime because PdM does not use intrusive inspections like the ones used by many PM tasks. These intrusive inspections require downtime and can induce infant mortality failures by introducing debris into the equipment or creating errors based on reassembly issues. These errors include improper torque on bolts or poor alignment on shafts as examples.

Figure 1. Equipment Failure Patterns.

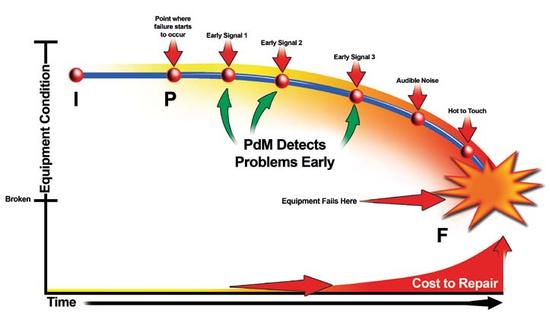

Figure 2. The P-F Curve.

This proclivity to introduce failures during assembly is demonstrated by the extremely high percentage of failures on the infant mortality curve from Figure 1. PdM allows us to avoid this potential problem. PdM is based on using technology that can “see, hear, feel and smell” the faults, even though they are all outside of the normal range of the human senses. The five most common PdM tools are:

- Ultrasonic, which “hears” faults in equipment

- Vibration, which “feels” faults in rotating equipment

- Oil Analysis, which “smells” chemical changes and “sees” wear particles in the oil

- Infrared, which “sees” changes in heat that can indicate possible faults

- Motor Current Analysis, which “sees” changes in frequencies and amplitude of electricity in motors, much like Vibration does for rotating equipment

Figure 1 demonstrated that only 11 % of the total failure modes were time based; therefore, 89 % of the existing failure modes cannot effectively be addressed with traditional time-based PM. Many of the 89 % can be effectively addressed with PdM.

The P-F curve is a model that shows how the PdM technologies provide you with additional time to plan and schedule needed repairs and lower total maintenance cost. PdM tends to identify defects much earlier and closer to Point P, which is the first time they can be detected. If we rely only on the human senses, then detection occurs closer to Point F, which is the functional failure. This late detection leads to emergency repairs and higher maintenance cost due to lack of planning, parts that must be expedited, and overtime that must be worked.

Precision Maintenance

The third “P” is Precision Maintenance. It is the opposite of percussion maintenance, which I have seen many maintenance craftspeople practice as a standard. Percussion maintenance is when a hammer is used to install new bearings or knock a motor into place on the stand. The better practice is Precision Maintenance, which is about using superior craft skills and the correct tools to ensure that the asset is properly installed and has as few infant mortality defects created as possible.

As we mentioned in our discussion about the first figure showing the failure curves, infant mortality is a major cause of downtime, and Precision Maintenance is by far the best way to address it. Precision Maintenance includes activities like:

- Shaft alignment,

- Rotating equipment balancing,

- Belt tensioning and alignment,

- Bolt torquing,

- Lubrication calculation, and

- Proper bearing installation using specialized tools such as bearing heaters and installation collars.

If the craftspeople in your facility practice these skills, then you will eliminate or postpone many failures.

Now, let us look at the benefit graphically, if you reference back to the P-F curve shown in Figure 2, you will notice a Point I representing the installation point prior to Point P. If we apply Precision Maintenance techniques, then we extend the I to P interval, which improves Mean Time Between Failures (MTBF) and, therefore, reduces operations downtime and maintenance cost. It is improved due to the fact that we are working at every maintenance-machine interaction to effectively meet the operational needs of the machine without committing errors that could induce failures. If it is installed correctly, started up correctly, and provided with the proper lubrication at the proper time, then we have mastered the act of Precision Maintenance.

Summary

As shown, if you can apply all three of the “Ps” to your maintenance organization, then you can create the step change in uptime and maintenance cost that is required in the competitive world we live in today. To bring it all together, Preventive Maintenance should be used for your time-based failures and the task must be failure mode-based with Precision Maintenance techniques applied. According to our studies 15 % of the work that your organization does should fall into this category.

Predictive Maintenance should be used for another 15 % of your work and should target to your random, non time-based failures so that they can be detected and the repairs planned and scheduled for correction using Precision Maintenance techniques. Finally, as I alluded to before, we should use Precision Maintenance with each of the other “Ps”. If we do, then PM and PdM will detect fewer failures and some failure modes may be eliminated entirely.

As failure modes become less common or are eliminated, the need for some PM and PdM inspections will lessen reducing the workload. Together, the three “Ps” generate a fourth “P” for those who take the time to use them correctly – increased Profit.

|

Shon Isenhour Director of Education, GPAllied Chairman of the Society for Maintenance and Reliability Professionals USA |

Tagged Maintenance, Precision, Predictive, Preventive, Shon Isenhour

Pingback: Tiffany prezzi