Industrial Maintenance

Wi-care wireless vibration and temperature condition monitoring system

Friction and lubrication under control: a mixer in chemical plant

Introduction

A few of the rotating machines in your plant have the criticality to bring production to a halt. On top of a shutdown system installed on this equipment to prevent catastrophic failure, it is interesting to think about having continuous health information about these machines. Roughly 50% of machinery damages, leading to downtime, are linked to process, and 90% of them are predictable – even manageable. The wireless vibration added values are well known and justify fully the use of Wi-care regardless of whether you want to revamp your actual wired system or install a completely new one.

The following case study describes and explains a typical remote analysis application of continuous friction/lubrication monitoring on a mixer in chemical plant. The continuous surveillance was set up in a very effective way for the customer and analyst:

For the Customer: Easy detection, fast diagnosis and monitoring from the friction issue on a critical mixer asset with low upfront investment and lower costs than manual/traditional online monitoring.

For the analyst: Continuous data, instant trend data and 24/7 protection, higher confidence without any travel or measurement time spent

The world is turning wireless, condition monitoring too!

Equipment, plant overview, Context

The Chemical site is a Phosphoric Acid Plant operating 24 Hours 7 days a week, established for many years in Africa. The Equipment in question is a large mixer involved in the acid production and a very large fan for production air treatment. Routine measurement performed with potable data collector indicated friction on both of these machines bearings. Cage frequency issues were detected, indicating higher than normal levels of friction. These raised levels would not warrant an immediate replacement but the next planned shutdown was in 10 months time. I-Care suggest the installation of Wi-care wireless vibration/temperature monitoring system and the analysis/trending by its remote team to ensure no premature escalation in the evolution of the defect.

The Wi-care system is set up on the main bearing housing of the mixer shaft.

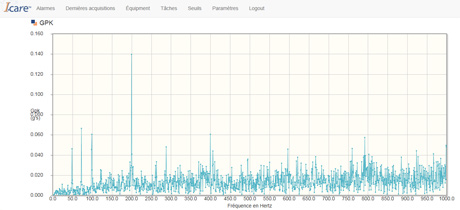

Outlined below is the standard spectrum collected with the Wi-care wireless monitoring system at the lower radial position. Display is in acceleration units G PK. The dominant frequency appears at 185 Hz and its harmonics. In addition there is a lot of random vibration/noise visible in the spectrum indicating friction

Analyst diagnosis and spectrum justification: Friction in mixer bearings

Wi-care data from May 2014.

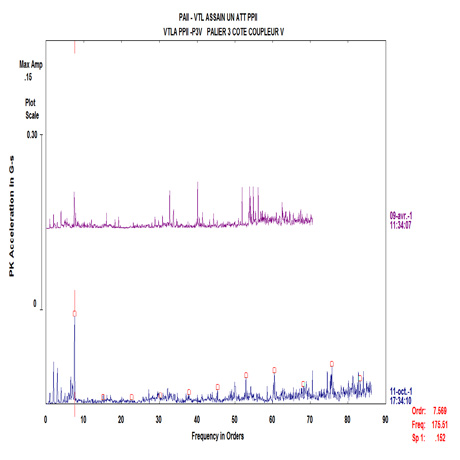

Seen below is a comparison of acceleration spectra made over a period of two measurements within 6 months. Measurement performed with CSI Data portable collector in April and October 2013

Portable analyzer data collection-April/October 2013

The friction is easy to identify with the portable data collector and the Wi-care wireless even though the levels are not high. The close attention to bearing lubrication levles based on Wi-care monitoring maintains a stable friction and avoidance of a decrease in bearing health.

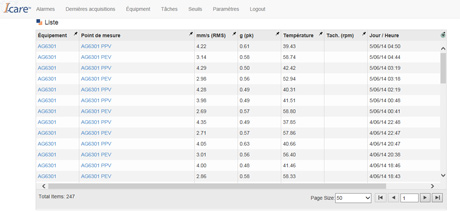

Following the diagnosis and remedial action, Wi-care provided a clear trending of data to the operators and predictive team

Wi-care latest set of data and trend

ROI and time frame

| COST | |

| Bearing replacement delay | 16 hours |

| Bearing replacement cost | 3000 € |

| Shaft and Bearing replacement | 20 000 € |

| Production loss | >40 000 € |

| Defect previous occurrence | 1 times/year |

| INVESTMENT | |

| Wi-care system +install+ close monitoring + expertise diagnosis + reporting | < 10 k€ |

Wi-care product and remote diagnosis overview

What it is?

The Wi-care™ system is the latest wireless condition monitoring system from I-Care. The system has been designed to detect, measure and analyse the root causes of excessive levels of vibration and temperature. The Wi-care system is a cost-effective tool used to report any vibration or temperature deviation in a short time. The I-CARE team of engineers using the data from Wi-care are able to give you a condition monitoring remote diagnosis at any time 24 hours a day/7 days a week. The condition based maintenance partnership has been created to give you the chance to correct a potential problem before it occurs.

The solution developed in the Wi-care system is based on a receiver connected on the internet and able to manage up to 144 transmitters, each transmitter sending vibration and temperature data. In order to reach long distance data transfer and remote locations, the WI-care involves a range extender in its network. Using a web-based portal to manage the system avoids any extra cost and any difficulties linked to software. We all know how frustrating it is when you are waiting for your data analysis and you can’t take any quick condition based maintenance decision due to software issues.

Added value?

Online monitoring based on permanent wired sensors can be expensive in many applications. Wireless monitoring with wireless vibration sensors improves the reliability of difficult-to-monitor assets with a quick and cost effective installation. Wireless vibration monitoring lends added value with a more flexible system, cutting expense and labour costs on installation and maintenance of the old wired vibration and temperature sensors. You attach the sensors using extra-strong magnets where you need them and in minutes they create a large network of real time data transmission to the gateway data manger in tandem with the range extenders. The solution created by Wi-care is very flexible and cost effective because it allows the reuse of existing piezoelectric vibration sensors and turns them into wireless vibration sensors with the single action of plugging the sensor into the wireless transmitter.

http://www.wirelessvibration.eu/added-values-wireless-vibration-sensor.html

Tagged chemical plant, Icare, lubrication, mixer

Pingback: informasi cpns 2017

Pingback: GVK Biosciences

Pingback: cara daftar sekolah online

Pingback: Shemale.UK